Pipeline monitoring

Pipeline Monitoring

IoT plays several roles in monitoring of pipelines. Operational data from electric submersible pump can be monitored to detect potential failure and automatically stop the pump to prevent damage, and in-turn notify operators to repair or replace the pump based on current machine and maintenance models. IoT can also be used in pipeline optimization, where it can shut down a valve and send an alert to a mobile device to avoid a major disruption or damage a pipeline. Using data analytics, you can monitor and report your water utilization, prevent leaks and predict potential issues with accuracy. Smart meters can help with loss of water due to leakage.

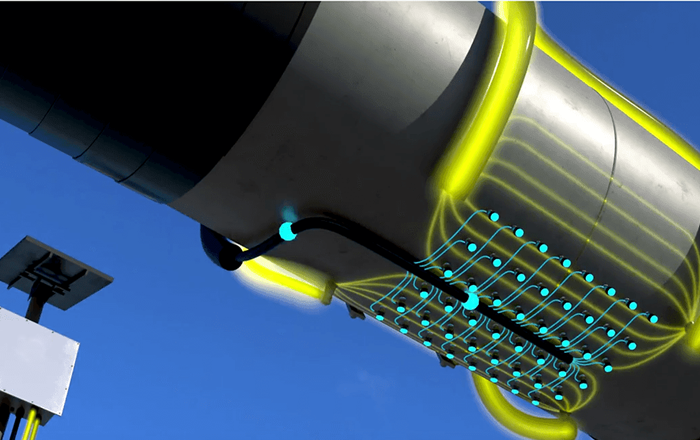

Flow measurement devices that enable accurate flows to be measured at a range of measurement intervals ranging from seconds to hours. Pipeline flow assurance is maintained in heated pipelines, which also optimizes energy usage. Continuous monitoring and real-time detection of issues inside a pipeline prevent severe damage to nature, assets, and personnel.

Pressure sensors offer the capability to detect and monitor dynamic pressure spikes, pulsations and surges in gaseous or liquid media.

Acoustic detection remains the primary means of detecting and locating pipeline leaks. The method of acoustic leak detection is described as “the systematic method of using listening equipment to survey the distribution system, identify leak sounds, and pinpoint the exact locations of hidden underground leaks.” Water escaping under high pressure from a pipe leak or crack makes a distinct rushing or hissing sound that can carry considerable distance along the length of the pipe itself

Pipeline monitoring system based on a sophisticated system which replicates the line while bypassing fluids, measuring corrosion rates in a chamber operating at system pressure and temperature, and returning the gas and fluid back into the pipeline.